| Drop Tester DT2000s |

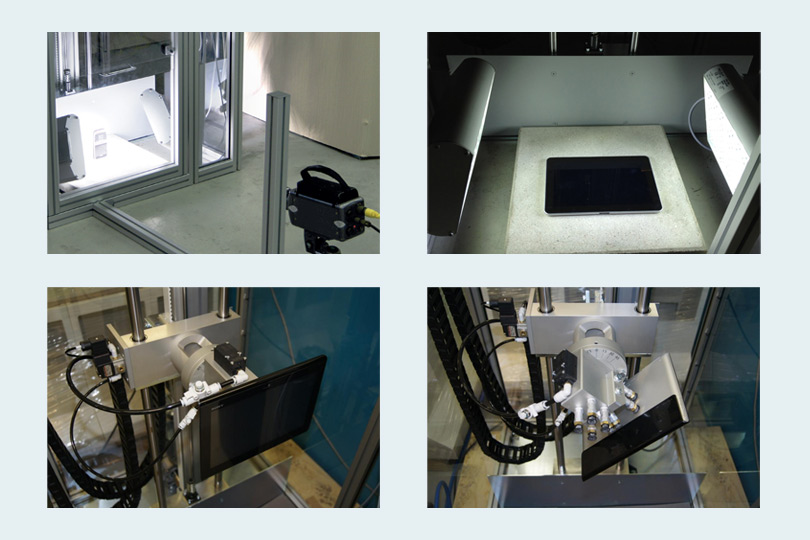

| with optional high speed camera |

| |

High-class drop testing

Heinä’s Drop Tester is used to test the breakage of various small items and components.

Operating principles

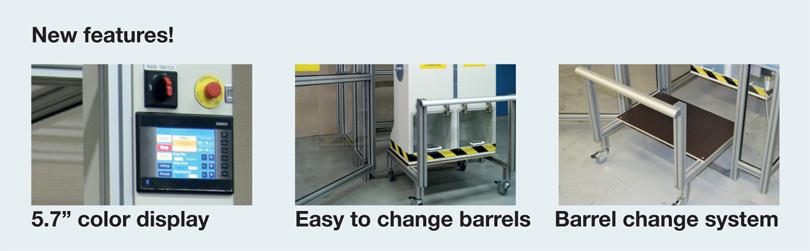

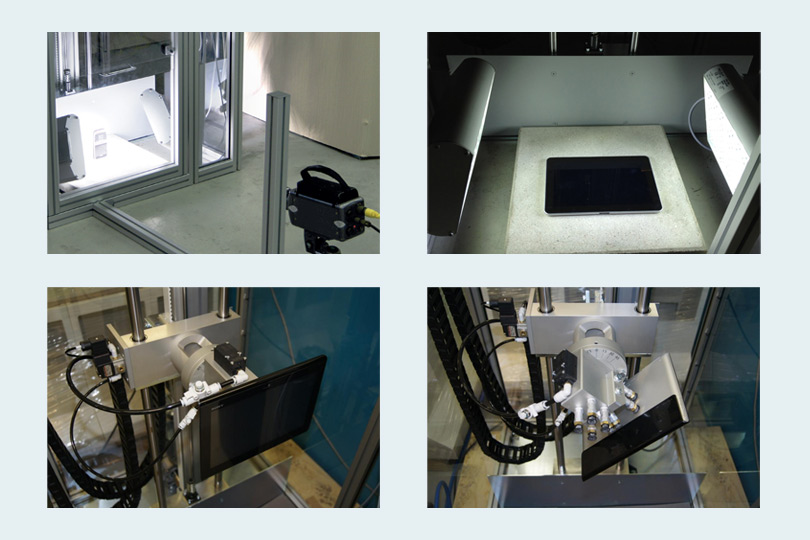

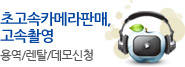

The item to be tested is attached to the suction pads of the machine and dropped from selected speed of 3,5 – 6,25 m/s or height of 600-2000 mm.

The dropping tray guides the item down towards the base in a right angle. With our Drop Tester you can also attach a high frequency video camera to the equipment in order to verify what actually happens, when the tested item hits the base of the machine.

The Drop Tester is conformable to the European Machine Directive 89/392 and its amendments 91/368, 93/44 and 93/68. |

| |

Special features Special features |

- Steady aluminium frame, reliable construction

- Safety gate, roof and electronic door lock

- IEC 60068-2-31 standard drop test

- IEC 60601-1 standard drop test

- Standard MIL-STD-810G,

Method 516.5

- CE certified

- Adjustable drop speed

- Adjustable drop height

- Reliable and accurate results with dropping tray

- Easy access to product for

inspection

- Presettable drop counter

- Inspection counter

- High frequency video camera

trigger output

- Different types of suction cups available

- Equipped with fast connector

|

| |

|

|

|

|

| |

|

| |

Technical specifications Technical specifications |

| Width |

900 mm |

Height |

2400 mm |

| Depth |

900 mm |

| Fall heights |

600–2000 mm |

Terminal velocity,

stepless adjustment |

3,5–6,25 m/s |

| Engine power |

0,25 KW |

| Air supply / Air Flow |

6 bar / 150 l/min |

| Electrical supply |

100–240 V, 50–60 Hz |

| Machine weight |

300 kg |

| Max item weight |

1 kg |

| CE-marking |

Yes |

| Drop platform |

Concrete block 400 x 400 x 50 mm |

|

| |

Go to http://www.heina.net/droptester/ Go to http://www.heina.net/droptester/

|

|

|

|

|

|

HOME

HOME

제품소개

제품소개

Drop & Tumble Tester

Drop & Tumble Tester

Special features

Special features